Beatrice Shilling’S Simple Fix That Saved WWII Fighter Pilots From Fatal Stalls

Have you ever wondered how a simple brass thimble helped turn the tide of World War II? When Britain's finest fighter planes were falling from the sky due to a deadly engine flaw, it wasn't a team of elite engineers who saved the day—it was one brilliant woman with a straightforward solution. Beatrice Shilling's ingenious fix for the Merlin engine's fuel system didn't just keep RAF pilots alive; it helped restore Britain's air superiority at a vital moment in history. You'll want to know how.

The Engineering Mind Behind the Wartime Innovation

The mind of an engineering prodigy emerged early in Beatrice Shilling's life. As a child, she spent her pocket money on tools and won a Meccano contest, foreshadowing her future talent for tackling engineering challenges.

By age 14, she'd bought her first motorcycle and taught herself to dismantle and rebuild its engine, demonstrating the hands-on approach that would define her career.

Her apprenticeship with electrical engineer Margaret Partridge helped lay the foundation for her future achievements.

Her practical skills, coupled with formal education as one of only two women studying engineering at the University of Manchester in 1932, shaped her unique approach to innovative solutions.

She earned both electrical and mechanical engineering degrees, then proved her expertise at the Royal Aircraft Establishment.

Her ability to combine theoretical knowledge with practical experience made her especially valuable in solving complex mechanical problems. Her racing prowess was evident when she achieved a Gold Star at Brooklands, reaching impressive speeds on her motorcycle.

A Deadly Flaw in Britain's Best Fighters

During the early days of World War II, Britain's premier fighters faced a potentially catastrophic design flaw that threatened their combat effectiveness.

The problem lay in their Merlin engines' carburettor design, which would flood with fuel during negative G maneuvers like steep dives. This challenge was similar to issues faced by the Heinkel He-100, which suffered from its own engine reliability problems.

When you're in a dogfight, the last thing you'd want is your engine cutting out – but that's exactly what British pilots faced. While German fighters could dive away freely thanks to their fuel-injection systems, RAF pilots couldn't pursue without risking engine failure. This critical issue affected many of the over 20,000 Spitfires produced during the war years.

The flaw forced them to perform a half-roll maneuver instead of diving directly, making them vulnerable in combat.

The root cause was the float-type carburettor system. During negative G forces, the float would rise, opening the fuel valve and disrupting engine performance with excess fuel.

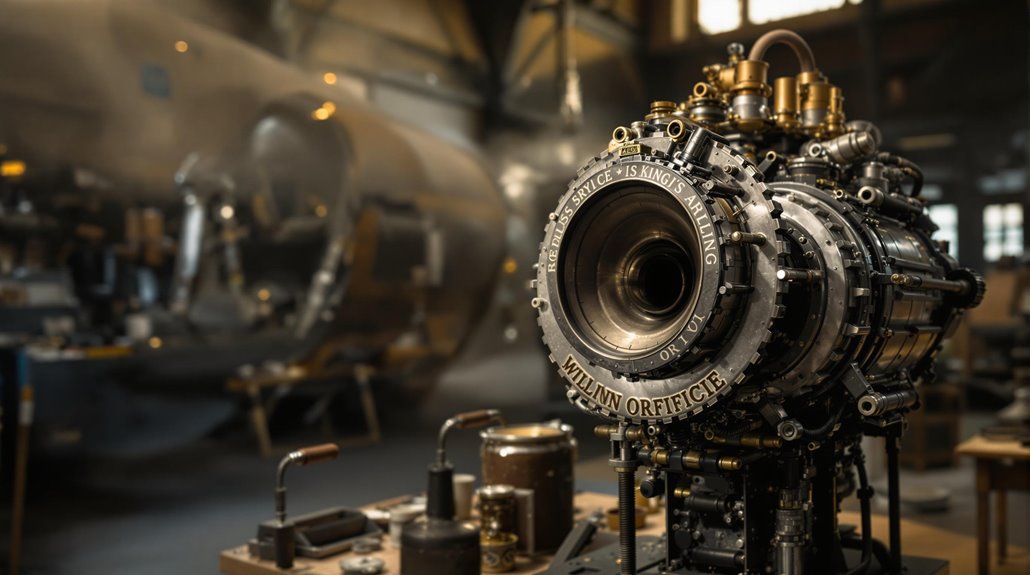

The Birth of Miss Shilling's Orifice

While RAF pilots struggled with stalling engines in combat, Beatrice Shilling emerged as an unlikely hero with an elegantly simple solution. Female scientific officers were rare at the Royal Aircraft Establishment when she worked there.

Her orifice design consisted of a basic brass thimble with a calibrated hole, which she later simplified to a flat washer. You'd be amazed that this tiny device could address such critical wartime challenges by restricting fuel flow just enough to prevent flooding while maintaining full power.

What made Shilling's solution brilliant was its practicality. Mechanics could weld the restrictor into engines right on the airfield, keeping planes in service. The invention proved especially vital during the Battle of Britain, when British pilots faced increased danger against the Luftwaffe's Messerschmitt 109s.

Though it didn't completely eliminate engine hesitation during negative-g maneuvers, her device prevented the dangerous 1.5-second rich cut that had plagued British fighters. The invention, affectionately dubbed "Miss Shilling's orifice," remained in use until pressure carburetors arrived in 1943.

Racing Against Time: Installation Across RAF Bases

In March 1941, Shilling's ambitious rollout of the RAE restrictor began across RAF fighter stations, marking a race against time to protect Britain's air fleet.

You'd find her leading a rapid response team, traversing the country on her motorcycle, installing the life-saving device in just minutes per aircraft without disrupting active service.

Despite significant logistical hurdles, including limited manufacturing capacity and complex coordination between RAE, RAF, and frontline bases, Shilling's team worked around the clock.

They prioritized squadrons based on combat frequency, while managing wartime transportation challenges.

Initially skeptical pilots quickly became advocates after seeing the device's effectiveness in combat situations, and mechanics appreciated that the hands-on engineering skills she demonstrated earned their respect despite her senior status.

Born on International Women's Day, she brought unmatched expertise to this critical wartime mission.

The results were immediate: Spitfires and Hurricanes could now match Luftwaffe aircraft in aggressive maneuvers, dramatically improving RAF's combat capabilities and saving countless pilot lives.

How a Simple Brass Device Changed Air Combat

A fatal flaw in the Rolls-Royce Merlin engine nearly cost Britain the air war until Beatrice Shilling engineered a brilliantly simple fix.

Her small brass disc with a precisely calibrated hole revolutionized combat efficiency for RAF fighters. By restricting fuel flow to the carburetor bowl, the device prevented engine cut-outs during negative-g maneuvers, allowing Spitfires and Hurricanes to dive aggressively after German aircraft. Before her innovation, pilots were forced to perform half-roll maneuvers before diving to maintain engine power. Like the Norden bombsight's development, the project maintained strict secrecy throughout the war years.

You'll appreciate how this seemingly modest innovation leveled the playing field against Luftwaffe fighters equipped with fuel injection systems.

The impact was immediate and decisive. RAF pilots could now execute complex combat maneuvers without fear of engine failure. This restored their competitive edge in dogfights, proving essential to pushing back the Luftwaffe.

Shilling's practical solution remained standard equipment until 1943, when pressure carburetors finally replaced it.

The Legacy of an Engineering Heroine

Beyond her revolutionary carburetor fix, Beatrice Shilling's remarkable career shattered gender barriers in engineering and motorsports. As one of Britain's pioneering women in the 1930s, she earned advanced degrees in electrical and mechanical engineering when few females entered these fields.

technical officer in 1939 demonstrated her exceptional capabilities during a critical period in history.

technical officer in 1939 demonstrated her exceptional capabilities during a critical period in history.

You'll find her influence in modern aviation, engineering curricula, and the growing presence of women in technical fields worldwide.