Tupperware’s Secret Stash: Earl Silas Tupper’s Plastic Trials in His Shed

Like a determined alchemist transforming base metals into gold, you'll find Earl Silas Tupper in his farm shed, converting industrial waste into household magic. In 1946, his tireless experiments with DuPont's polyethylene slag led to more than just another plastic container—they sparked a revolution in how you store your leftovers. But before his iconic seal changed kitchens forever, Tupper's journey through failure and innovation reveals an unexpected path to success that might surprise you.

From Farm Boy to Plastic Pioneer

Growing up on farms in central Massachusetts, Earl Tupper showed entrepreneurial spirit from an early age. By age 10, you'd find him revolutionizing his family's income through door-to-door produce sales, proving more effective than traditional farming methods.

His childhood innovation emerged from watching his father create labor-saving devices for their farm and greenhouses. You can trace Tupper's inventive mindset to his youth, when he earned a patent for a chicken-cleaning frame. His early experiences with invention would later help him develop the revolutionary nonsnap lid for food containers.

After graduating high school in 1925, he worked various jobs including mail clerk and railroad crew member before studying tree surgery. This led him to launch Tupper Tree Doctors in 1928, running a successful landscaping business until the Great Depression forced bankruptcy in 1936.

Undeterred, he joined DuPont's plastics division in 1937, setting the stage for his future success. In 1938, he took a bold step forward by establishing Earl S. Tupper Company.

A Backyard Lab of Dreams

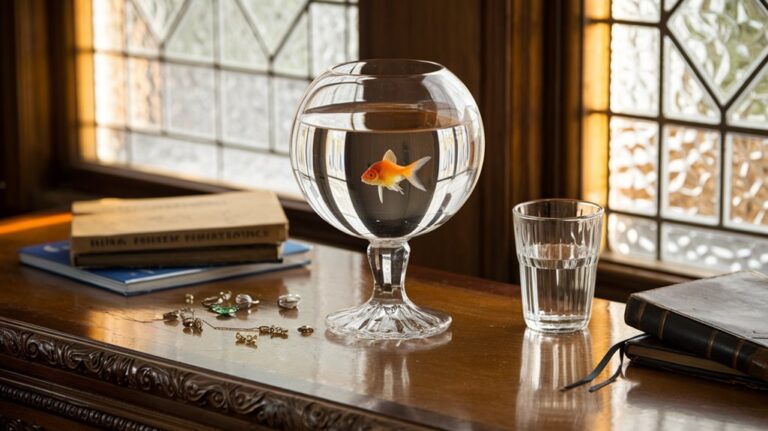

While working at DuPont during the day, Earl Tupper transformed his family's humble farm shed into a makeshift laboratory where he'd spend countless nights and weekends pursuing his plastic dreams.

In this unassuming backyard lab, you'd find him tinkering with black polyethylene slag, a waste product he'd obtained from DuPont. His early creativity shone through as he used farm invention skills from his youth. His shed innovations began with basic tools as he purified and molded the rigid material into lightweight containers. After earning one year's training at Viscoloid, he applied this knowledge to refine his techniques.

Through persistent experimentation, he conquered the plastic's brittleness and odor-retention problems, eventually developing a method to create clear, odorless products.

His early prototypes ranged from gas masks for World War II to cigarette cases and bathroom tumblers.

But his most significant breakthrough came in 1946 when he created the paint can-inspired airtight seal that would revolutionize food storage containers.

The DuPont Years That Shaped His Vision

Although Earl Tupper's time at DuPont lasted just one year, his 1937 stint in the company's Viscoloid plastics division laid the foundation for his future innovations.

The DuPont legacy would follow him throughout his career, as he continued to leverage the company's resources and connections even after his departure. His experiments eventually led to the creation of the famous watertight seal that revolutionized food storage.

After facing early bankruptcy with his tree surgery business, Tupper's plastics education at DuPont proved indispensable. He gained critical knowledge in injection molding techniques and secured essential polyethylene materials for his experiments.

When he launched the Earl S. Tupper Company in 1938, he maintained strong ties with DuPont, which helped him land defense contracts during World War II. His company produced key military components like gas mask parts and Navy signal lamp elements.

This strategic relationship ultimately enabled him to develop the revolutionary Poly-T plastic that would transform food storage forever.

Breaking Through With Poly-T

The transformation of raw polyethylene slag into Poly-T marked Tupper's defining breakthrough. You'd hardly recognize the original material – a black, putrid slag that became an odorless, non-toxic wonder plastic under Tupper's expertise.

The Poly-T properties were revolutionary. You could expose it to near-boiling water, flex it repeatedly, and trust its durability far beyond traditional styrene. While sharp knives could damage it, you'd find it nearly indestructible in everyday use. As DuPont's supplier, Tupper's company manufactured various molded parts during World War II. His early experiments benefited from DuPont's sample maker program that provided materials for testing.

Tupper's Poly-T innovations emerged from countless experiments in his home, where he and his son discovered the perfect pressure-temperature balance.

They'd created a versatile material that soon found its way into Navy equipment and household goods. Most importantly, it became the foundation for Tupperware's air-tight containers that would transform food storage forever.

The Magic Seal That Changed Everything

Before Earl Tupper perfected his revolutionary seal design in 1947, you'd find most households struggling with unreliable food storage options. His seal innovation, inspired by paint can lids, transformed food storage forever with its ingenious double-seal mechanism that you could open and close by simply pressing the center.

You'll appreciate how Brownie Wise dramatically showcased this airtight technology at Tupperware parties, tossing Wonder Bowls filled with grape juice across living rooms without spilling a drop. She taught housewives to "burp" their containers, demonstrating a completely new way to preserve freshness. The durable, colorful polyethylene material used in manufacturing made these containers practically indestructible.

At just 39 cents, the Wonder Bowl offered you an affordable solution that would outperform any existing storage option. This wasn't just another container – it was a revolution that would generate billions in sales and redefine how you store food.