From Failed Soup Can to Game-Changing Molded Plastic: How Leo Baekeland Pioneered Bakelite

Picture yourself holding a vintage rotary telephone from the 1920s – its glossy black housing was likely made from Bakelite, the world's first synthetic plastic. You've probably used dozens of plastic items today without considering their revolutionary origins. While modern polymers fill our lives, it wasn't until Leo Baekeland's persistent experiments with phenol and formaldehyde that the age of synthetics truly began. His story of persistence through failure reveals how one chemist's determination changed the modern world.

The Early Years: a Chemist's Journey From Belgium to America

While many great inventors start from humble beginnings, Leo Baekeland's journey from a cobbler's son in Ghent, Belgium, to becoming a pioneering chemist in America exemplifies the power of scientific passion and determination.

His early influences included a deep fascination with chemistry, which led him to excel at the Koninklijk Atheneum and earn his doctorate from the University of Ghent. He completed his PhD with maxima cum laude distinction at just twenty-one years old.

Despite facing academic challenges in a new country, Baekeland's expertise in chemistry and photography caught the attention of Professor Charles Chandler at Columbia University.

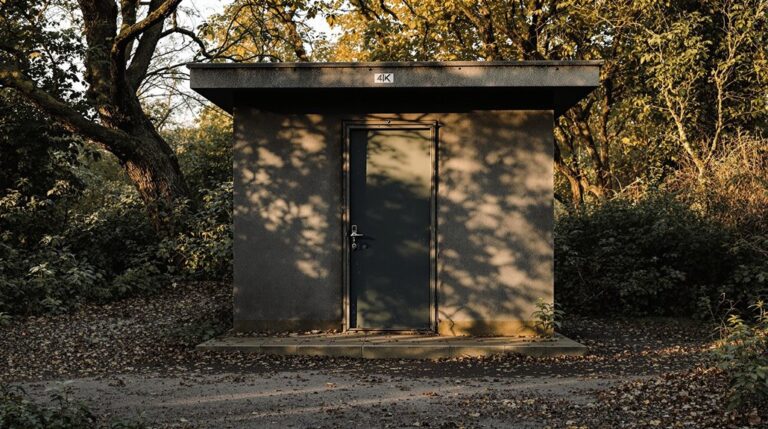

After immigrating with his wife in 1889, he established himself as a consulting chemist in New York, converting a barn into his laboratory at Snug Rock estate.

There, he'd begin his groundbreaking work with phenol-formaldehyde resins, though not without initial financial struggles.

His move to America was accompanied by his beloved wife Céline Swarts, marking the beginning of their new life together.

Velox: The Million-Dollar Stepping Stone

Baekeland's early struggles in America soon gave way to his first major breakthrough: Velox photographic paper. The Velox innovation, developed in 1893, revolutionized photography by allowing development under artificial light, unlike existing sunlight-dependent papers.

To manufacture his invention, he founded the Nepera Chemical Company in Yonkers with partner Leonard Jacobi. The venture proved remarkably successful. Within six years, George Eastman of Kodak purchased the Velox rights and company for nearly $1 million – equivalent to over $30 million today.

This windfall granted Baekeland the financial freedom to pursue his true passion: chemical research. He established a home laboratory at his Snug Rock estate, where he focused on experiments with phenol and formaldehyde. After completing his studies at the University of Ghent as a maxima cum laude graduate, his dedication to scientific advancement never wavered. His extensive work would later be preserved in student notebooks and laboratory journals documenting his chemical discoveries.

These studies ultimately led to his groundbreaking invention of Bakelite in 1907.

The Quest for Synthetic Shellac

As the electricity boom of the early 20th century intensified, manufacturers faced a critical shortage of shellac, a natural insulator harvested from Asian lac beetles.

The supply challenges were staggering – it took 7,500 beetles an entire year to produce just one pound of shellac, and harvesting required intensive manual labor to scrape deposits from trees.

Enter Leo Baekeland, who saw an opportunity for industrial innovation. He began investigating phenol-formaldehyde reactions in 1904, spurred on by rising camphor prices during the Russo-Japanese War.

While his first attempt at synthetic shellac, called Novolak, wasn't commercially successful, it led him down a fascinating path. His experiments on June 18, 1907, marked the start of what would become the world's first synthetic plastic.

Rather than focusing solely on wood coatings, he explored wood impregnation and molding applications, ultimately developing the groundbreaking plastic we're familiar with as Bakelite. His innovative process required careful temperature control to produce the durable material that would revolutionize manufacturing.

The Birth of Bakelite: A Revolutionary Discovery

Following years of groundbreaking research in chemistry, Leo Baekeland made a discovery in 1907 that would transform modern manufacturing forever.

Through experiments with phenol and formaldehyde, he stumbled upon a revolutionary process while searching for a synthetic shellac alternative. The key breakthrough came when he learned to control temperature and pressure during the chemical reaction. In his converted barn laboratory in Yonkers, he conducted countless experiments to perfect his formula.

What made Bakelite properties so remarkable was its versatility as a thermosetting plastic.

You'll find it's heat-resistant, electrically insulating, and incredibly durable. The material quickly became the preferred electrical insulator in numerous manufacturing applications.

After Baekeland's public announcement in 1909 to the American Chemical Society, Bakelite applications exploded across industries.

The material, which he dubbed "polyoxybenzylmethylenglycolanhydride," could be molded into countless shapes and colors, earning it the nickname "the material of a thousand uses."

A World Transformed by the First Synthetic Plastic

The invention of Bakelite triggered a manufacturing revolution that would reshape daily life in the 20th century.

By combining formaldehyde and phenol under intense heat and pressure, Leo Baekeland created this groundbreaking synthetic material.

You'd find this versatile material everywhere, from the radio in your living room to the jewelry around your neck. As "the material of a thousand uses," Bakelite transformed both consumer products and industrial applications. The rise of Bakelite marked the beginning of an era where plastic production doubled with each passing decade.

You couldn't escape its influence in wartime either. Military equipment like pilots' goggles and field telephones relied on Bakelite's durability.

In homes, it revolutionized electrical devices with improved insulation for plugs and switches. The material's impact extended into design, making Art Deco aesthetics accessible to the masses through affordable, molded products.

Today, while modern plastics have largely replaced it in consumer goods, you'll still find Bakelite in specialized industrial applications, from electronics to aerospace, proving its lasting legacy.

Scientific Recognition and Industrial Leadership

Behind Bakelite's sweeping commercial success stood Leo Baekeland, a brilliant scientist whose achievements extended far beyond this revolutionary material. His scientific impact began early, earning his PhD with highest honors at just 21 from the University of Ghent.

pragmatic innovator helped bridge the growing gap between academic research and industrial applications in the early 20th century. Bakelite proved revolutionary as the world's first synthetic plastic, transforming countless industries.

pragmatic innovator helped bridge the growing gap between academic research and industrial applications in the early 20th century. Bakelite proved revolutionary as the world's first synthetic plastic, transforming countless industries.

You'll find his genius reflected in 119 patents and groundbreaking research on phenol-formaldehyde reactions that transformed materials science.

Baekeland's industrial innovation matched his academic prowess. He founded the General Bakelite Company in 1910, skillfully growing it into a global powerhouse through strategic mergers with Condensite and Redmanol.

The scientific community celebrated his contributions with prestigious honors, including the Perkin Medal and Franklin Medal. His appointment to Columbia University and election to the National Academy of Sciences further cemented his legacy as both a pioneering researcher and business leader.