Roman Concrete vs. Modern Concrete: Why We’re Losing

You might find it remarkable that ancient Roman structures have outlasted most modern buildings, despite our technological advances. When you compare the Pantheon's pristine dome to the crumbling highways of today, you'll notice a striking difference in durability. While today's construction industry champions rapid development and cost-cutting measures, the Romans embraced a slower, more methodical approach that yielded superior results. Understanding this contrast holds the key to revolutionizing our current building practices.

The Ancient Secret Behind Roman Concrete's Durability

While modern engineers have long marveled at the longevity of Roman concrete structures, scientists have finally uncovered the ancient secret behind their remarkable durability.

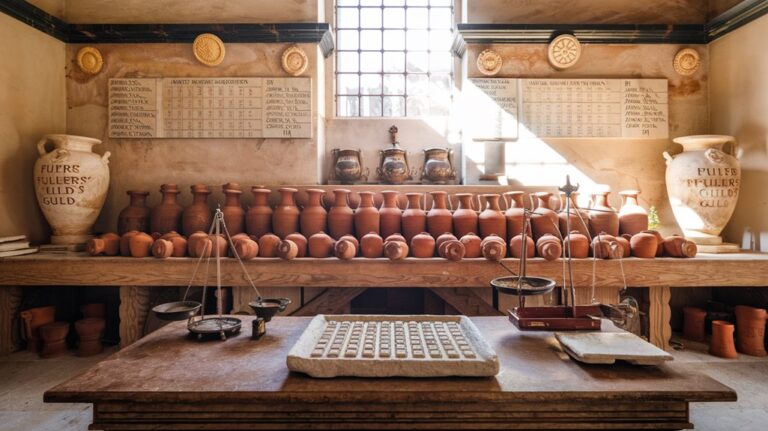

The answer lies in the unique combination of sustainable materials and ancient techniques used in their mixture. You'll find that Roman builders created their concrete using volcanic ash, quicklime, and carefully selected aggregates like rock and ceramic tile. Ancient builders also developed structures that featured gradual density changes from foundation to dome, enhancing their stability.

When mixed with seawater, these components formed rare crystals called tobermorite, which prevented fracturing.

What's most fascinating is the self-healing property of their concrete, achieved through hot-mixing with quicklime. This process created lime clasts that, when exposed to water, could form new calcium carbonate crystals to naturally repair cracks – a feature that's helped these structures survive for over 2,000 years. The discovery could help reduce global carbon emissions since concrete production currently accounts for 8% of this environmental impact.

Modern Concrete's Environmental Impact: A Growing Crisis

Modern concrete's environmental footprint stands in stark contrast to its Roman predecessor's sustainable nature. When you look at today's concrete industry, you'll find it's responsible for a staggering 5% of global carbon emissions, with each ton of cement releasing 780 kg of CO2 into the atmosphere.

The environmental crisis doesn't stop at carbon emissions. You're witnessing unprecedented resource depletion as the industry consumes 10% of the world's industrial water supplies, with most withdrawals occurring in already water-stressed regions. New technologies involving carbon capture sequestration are being developed to help mitigate these devastating effects.

The damage extends to biodiversity loss, as concrete smothers natural habitats and disrupts ecosystems. The industry's activities cause extensive damage to topsoil, leading to increased surface runoff and flooding risks. In urban areas, you'll feel the impact through heat island effects, raising temperatures by up to seven degrees Fahrenheit.

The industry's toll on human health is equally concerning, with cement production releasing toxic substances that cause respiratory issues.

Self-Healing Properties: Nature's Engineering Marvel

Unlike its modern counterpart, ancient Roman concrete showcases remarkable self-healing properties that you won't find in today's standard mixtures. When exposed to seawater, Roman concrete's unique blend of volcanic ash and quicklime triggers the formation of rare minerals like tobermorite, allowing the material to flex rather than crack under stress.

While modern concrete relies on engineered self-healing mechanisms through capsules or tubes containing healing agents, Roman concrete's natural process proves more effective. Research has shown that stratlingite crystals contribute significantly to the self-healing capabilities discovered in Roman concrete. The ancient mixture's integration of volcanic materials was inspired by observations following volcanic eruptions.

You'll find that today's autonomous healing techniques can repair larger cracks, but they're complex and often unreliable. In contrast, Roman concrete's interaction with seawater continuously strengthens the material over time, explaining why ancient structures have endured for centuries.

This profound durability highlights how much we still need to learn from ancient engineering wisdom.

The Cost of Quick Construction

The emphasis on rapid construction in today's building industry comes at a significant price.

You'll find that a staggering 85% of modern projects face cost overruns, with budgets typically exceeding initial estimates by 28%. While you might think faster construction timelines save money, the reality often proves otherwise.

When you rush the design process and accelerate construction phases, you're exposing your project to increased risks and quality control issues. Modern concrete's rapid curing time creates shrinkage strains that lead to problematic cracking. The use of traditional masonry systems remains one of the most economical and proven methods, despite being slower.

Construction costs are already rising globally at 4.6%, with some regions experiencing even steeper increases. The drive for speed often compromises long-term durability, unlike Roman concrete structures that have endured for centuries.

While modern methods like thin-joint blockwork and quick-curing concrete might reduce initial timelines, they can lead to premature deterioration and higher lifetime costs.

Coastal Construction: Learning From Roman Engineering

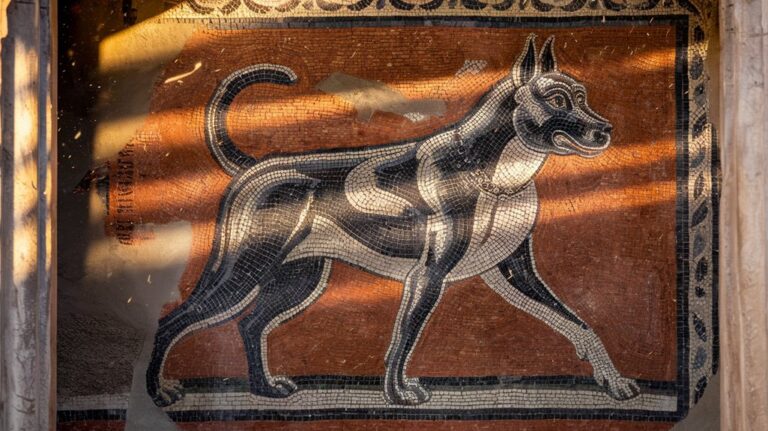

While coastal builders today grapple with deteriorating seawalls and failing foundations, ancient Roman structures continue to stand strong after two millennia of battling ocean waves. Their innovative construction techniques offer invaluable lessons for modern coastal resilience strategies.

You'll find Roman engineering marvels everywhere along the Mediterranean, from their hydraulic concrete that hardened underwater to their sophisticated breakwater systems. They mastered silt management through clever harbor designs and used floating cellular caissons for deep-water construction. The Romans revolutionized harbor construction by replacing Greek designs with vertical concrete walls.

Their concrete, mixed with volcanic ash and quicklime, actually grew stronger when exposed to seawater, forming protective minerals like tobermorite.

Today's coastal engineers would benefit from studying these time-tested methods, especially considering modern concrete structures often fail within decades in marine environments.

Bridging the Gap: Lessons for Future Innovation

By examining the stark differences between ancient Roman and modern concrete technologies, engineers can forge innovative solutions that combine the best of both worlds.

You'll find that sustainable materials like volcanic ash and locally sourced aggregates played an essential role in Roman concrete's durability, while modern innovative techniques focus on incorporating SCMs and nanoparticles to enhance performance. Modern concrete structures require careful planning due to their thermal movement characteristics. The superior salt resistance of Roman concrete makes it an invaluable model for coastal construction projects.

The future of concrete lies in bridging this technological gap.

You can see this happening through the development of self-healing concrete embedded with bacteria, smart monitoring systems, and 3D printing applications.

These advances address both durability and environmental concerns.