Roman Concrete vs. Ours: Why They Still Win

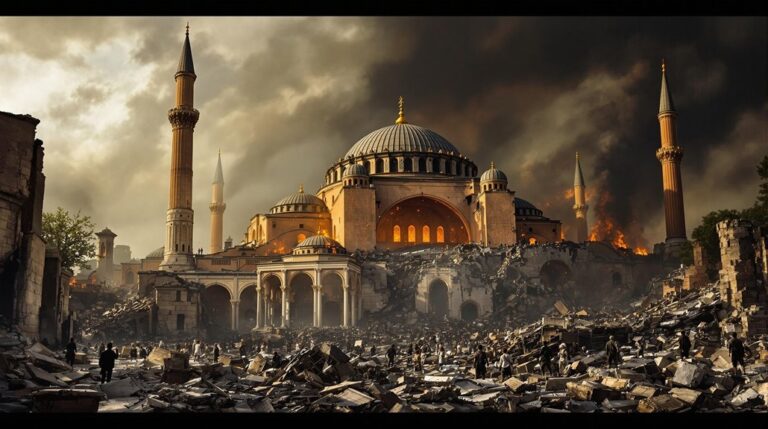

You've probably walked past modern concrete structures without giving them much thought, but there's an engineering marvel that deserves your attention. While today's buildings might last decades, ancient Roman structures have endured for millennia, withstanding earthquakes, wars, and relentless weathering. The contrast between these construction methods isn't just about age—it's about a lost art of engineering that modern science is still struggling to fully understand. As our infrastructure crumbles decades after completion, the enduring strength of Roman concrete continues to challenge our assumptions about progress and technological superiority.

The Secret Behind Ancient Engineering

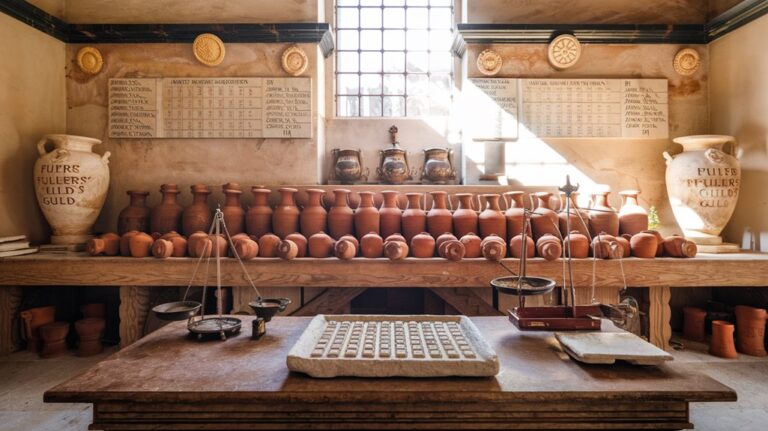

While modern engineers continue to marvel at Roman structures that have endured for millennia, the secret behind their longevity lies in an ingenious combination of materials and techniques.

The ancient materials, particularly the mixture of volcanic ash and lime, created a remarkable chemical reaction when exposed to saltwater, forming durable Tobermorite crystals. Hot mixing with quicklime produced unique chemical bonds that strengthened the concrete even further.

What's even more fascinating is how innovative techniques enhanced these materials' performance. This mastery enabled them to construct the Alcántara bridge span that still stands after nearly 2000 years.

You'll find that Romans mastered the art of concrete placement using methods like cofferdams for underwater construction and the box method for breakwaters.

They didn't just pour concrete; they developed self-healing properties within it.

When you examine their engineering closely, you'll discover they weren't simply building structures – they were creating living monuments that could repair themselves over time.

Modern Solutions Create Modern Problems

Despite their advanced capabilities, modern concrete solutions have created a host of environmental, health, and durability challenges.

When you look at today's construction practices, you'll find sustainability issues at every turn. Concrete production generates massive CO2 emissions, while the incorporation of toxic materials like coal ash poses serious health risks to workers and nearby communities.

The improper storage and use of coal ash containing mercury and arsenic continues to threaten public health. Regular maintenance requirements make traditional concrete more costly over its lifetime compared to sustainable alternatives.

You're also facing significant durability problems with modern concrete. Unlike its Roman counterpart, today's concrete often fails after just a few decades due to cracking, corrosion, and freeze-thaw damage.

The economic impact is substantial, as you'll need to balance high material costs with regulatory compliance and ethical sourcing requirements.

When you consider that concrete, aluminum, and steel account for 23% of global emissions, it's clear that our modern solutions need serious reconsideration.